Industrial electrical installations demand robust infrastructure that can withstand decades of service while maintaining safety and performance standards. The selection of appropriate materials for cable management systems directly impacts long-term operational costs, maintenance requirements, and system reliability. Modern facilities require cable trays that can endure harsh environmental conditions, support substantial cable loads, and resist degradation over extended periods. Understanding the material properties that contribute to durability enables engineers and facility managers to make informed decisions that optimize both initial investment and lifecycle performance.

Steel Construction for Maximum Load Bearing Capacity

Hot-Dip Galvanized Steel Properties

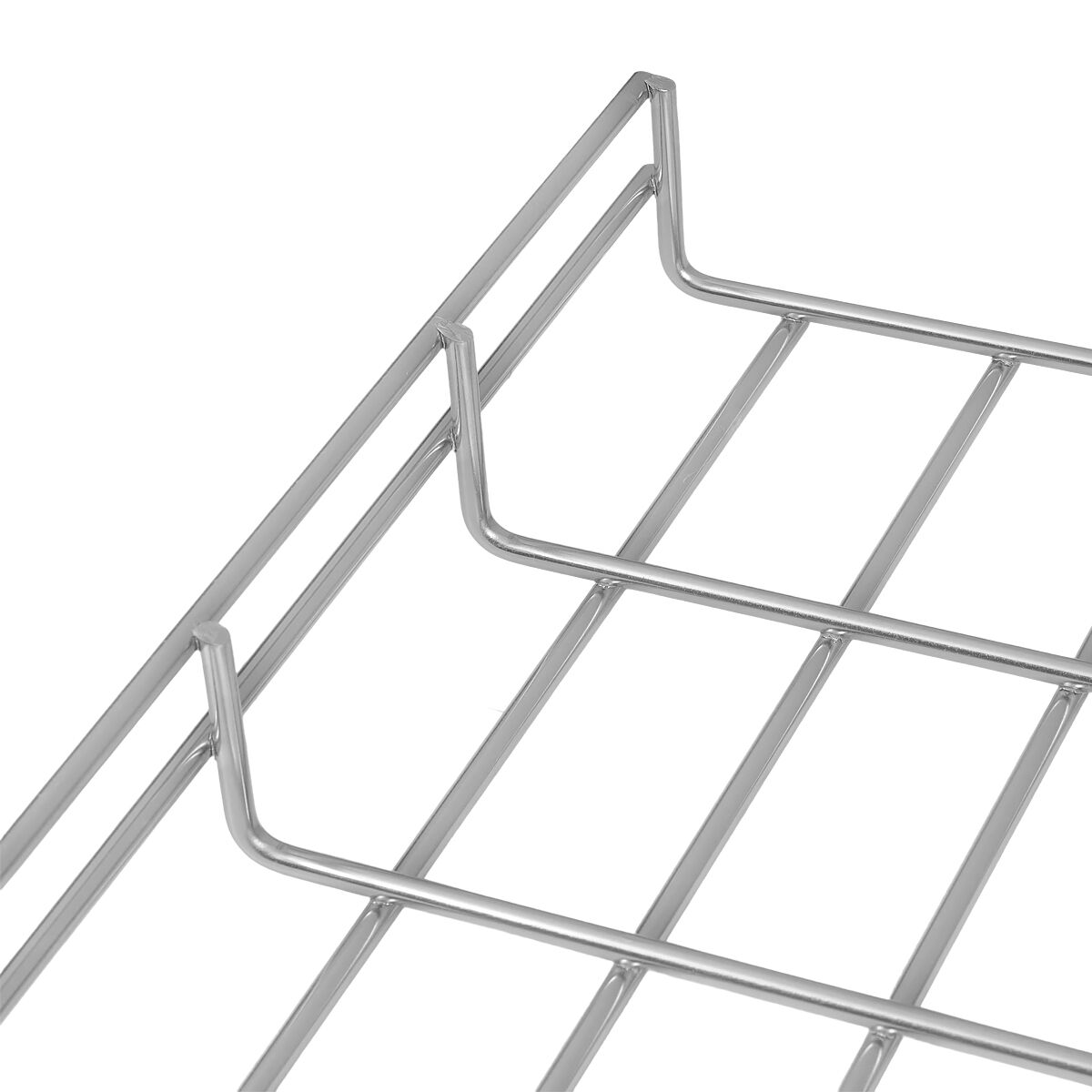

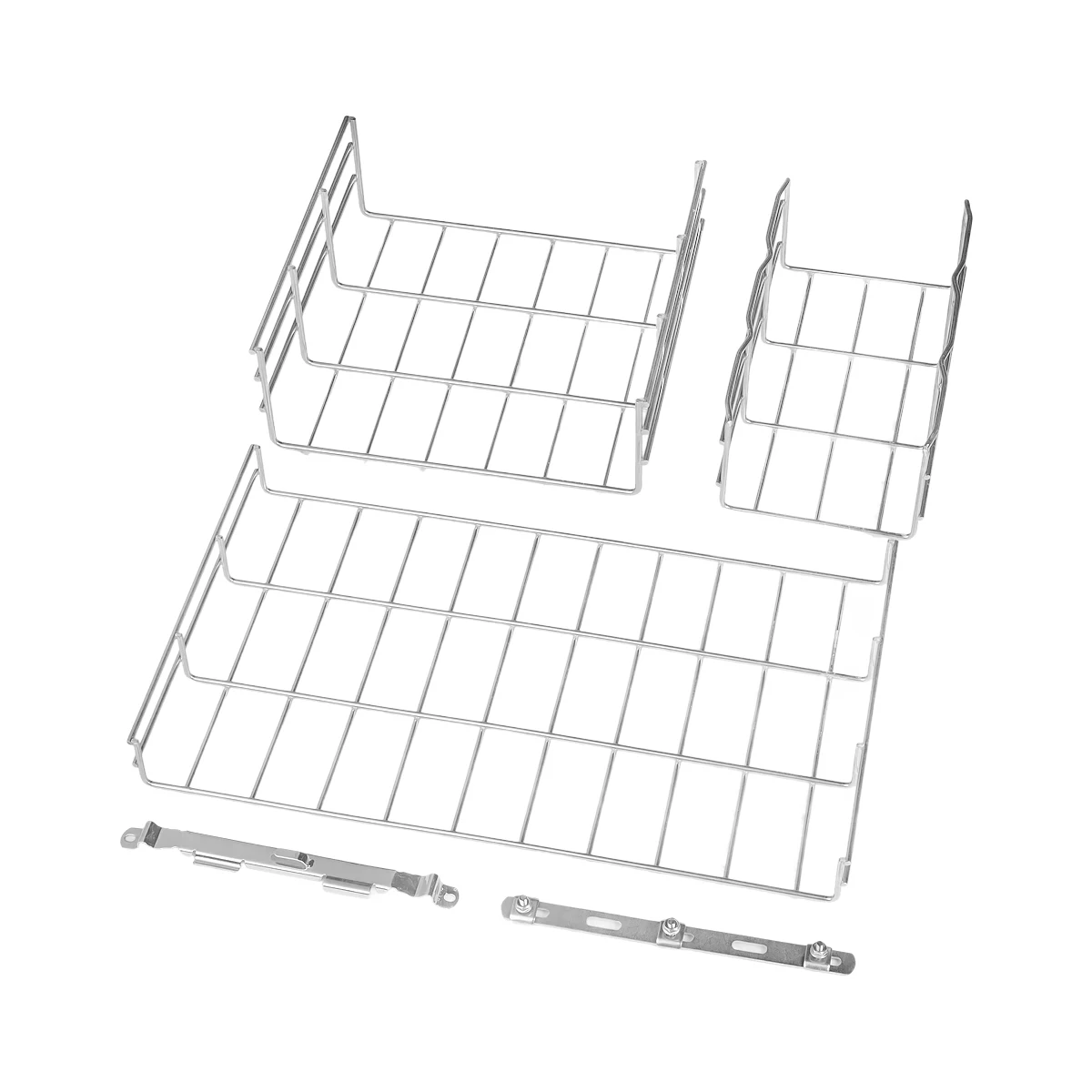

Hot-dip galvanized steel represents the gold standard for cable trays in heavy-duty industrial applications. This manufacturing process involves immersing fabricated steel components in molten zinc, creating a metallurgical bond that provides exceptional corrosion resistance. The zinc coating thickness typically ranges from 45 to 85 microns, depending on the steel thickness and application requirements. This protective layer sacrificially corrodes before the underlying steel, extending the service life of cable trays to 25-50 years in most environments. The galvanizing process also creates a self-healing characteristic where minor scratches or abrasions automatically develop protective patina.

The mechanical properties of galvanized steel cable trays make them ideal for spanning long distances without intermediate supports. Load-bearing capacities can exceed 150 pounds per linear foot for standard ladder-type configurations, while maintaining structural integrity under dynamic loading conditions. Temperature stability remains excellent across industrial operating ranges, with minimal thermal expansion coefficients that prevent binding or warping. The magnetic properties of steel also facilitate easy installation of cable supports and accessories using magnetic mounting systems.

Stainless Steel for Extreme Environments

Stainless steel cable trays offer superior performance in corrosive environments where galvanized steel may prove insufficient. Grade 316L stainless steel contains molybdenum additions that enhance resistance to chloride-induced pitting and crevice corrosion, making it suitable for marine, chemical processing, and food industry applications. The passive oxide layer that naturally forms on stainless steel surfaces provides self-renewing protection against atmospheric corrosion, eliminating the need for periodic coating maintenance. Service life expectations for stainless steel cable trays often exceed 50 years in aggressive environments.

The non-magnetic properties of austenitic stainless steels prevent interference with sensitive electronic equipment, making these cable trays particularly valuable in data centers and telecommunications facilities. Fabrication flexibility allows for complex routing configurations while maintaining smooth surfaces that minimize cable pulling forces during installation. The high strength-to-weight ratio of stainless steel enables longer spans and reduced support structure requirements compared to other materials.

Aluminum Alloy Solutions for Weight-Sensitive Applications

Corrosion Resistance Through Anodization

Aluminum cable trays provide excellent durability while offering significant weight advantages over steel alternatives. The natural oxide layer that forms on aluminum surfaces provides inherent corrosion protection, which can be enhanced through anodization processes. Anodized aluminum cable trays feature controlled oxide layers up to 25 microns thick, creating hard, wear-resistant surfaces with improved aesthetic appearance. The porous nature of anodized coatings allows for color integration and enhanced adhesion of supplementary protective treatments when required for specific environments.

Aluminum alloys commonly used in Cable Trays include 6061-T6 and 6063-T5 grades, which offer optimal combinations of strength, corrosion resistance, and formability. These alloys maintain structural properties across wide temperature ranges and resist stress corrosion cracking in most industrial environments. The thermal conductivity of aluminum also provides natural heat dissipation for power cables, reducing derating requirements and improving current-carrying capacity.

Lightweight Installation Benefits

The density advantage of aluminum cable trays significantly reduces installation labor and support structure requirements. Weighing approximately one-third as much as equivalent steel systems, aluminum cable trays enable longer shipping lengths and easier manual handling during installation. Reduced dead loads translate to smaller support brackets, lighter ceiling attachment hardware, and simplified seismic bracing requirements. The material's excellent machinability allows for field modifications and custom fittings without specialized tooling or hot work permits.

Aluminum's non-sparking properties provide safety advantages in hazardous locations where ignition risks must be minimized. The material maintains ductility at low temperatures, preventing brittle failure modes that can affect other materials in extreme cold conditions. Thermal expansion characteristics of aluminum are predictable and manageable through proper expansion joint placement and support design.

Fiber Reinforced Plastic Composite Materials

Chemical Resistance and Environmental Durability

Fiber reinforced plastic (FRP) cable trays offer exceptional chemical resistance and environmental durability in applications where metallic materials face limitations. Constructed from glass fiber reinforcements embedded in polyester, vinyl ester, or epoxy resin matrices, these composite materials resist attack from acids, bases, salts, and organic solvents. The non-conductive nature of FRP eliminates concerns about galvanic corrosion and electrical continuity issues that can affect metallic cable trays in certain installations. Service life expectations for properly designed FRP cable trays range from 30 to 50 years with minimal maintenance requirements.

UV stability of FRP cable trays depends on resin selection and surface treatment, with gelcoat or UV-resistant topcoats providing decades of outdoor exposure resistance. The material maintains mechanical properties across temperature ranges from -40°F to 200°F, making it suitable for both indoor and outdoor installations. Fire-retardant formulations meet strict flame spread and smoke generation requirements for building code compliance while maintaining structural integrity during fire exposure.

Electrical Isolation and Safety Benefits

The dielectric properties of FRP cable trays provide inherent electrical isolation that enhances safety in electrical installations. This characteristic eliminates the need for bonding and grounding requirements associated with metallic cable trays, simplifying installation and reducing material costs. The non-magnetic nature of FRP prevents interference with sensitive electronic equipment and eliminates concerns about eddy current losses in high-frequency applications. These properties make FRP cable trays particularly valuable in hospitals, laboratories, and telecommunications facilities where electromagnetic compatibility is critical.

Impact resistance of modern FRP cable trays exceeds that of many traditional materials, providing durability against mechanical damage during installation and service. The smooth interior surfaces minimize cable jacket abrasion during installation and thermal cycling, extending cable service life. Dimensional stability under load prevents sagging that can create cable stress points and binding in conduit connections.

Surface Treatment Technologies for Enhanced Protection

Powder Coating Applications

Powder coating technology provides superior finish durability and environmental protection for cable trays compared to traditional liquid paint systems. The electrostatic application process creates uniform coating thickness ranging from 50 to 100 microns, ensuring complete coverage of complex geometries including internal surfaces and weld zones. Thermosetting powder formulations cure to form crosslinked polymer networks that resist chipping, scratching, and chemical attack. Color stability and gloss retention remain excellent throughout decades of service, maintaining aesthetic appearance while providing functional protection.

Polyester and polyurethane powder coatings offer different performance characteristics suited to specific environments. Polyester systems provide excellent weatherability and UV resistance for outdoor applications, while polyurethane formulations offer superior chemical resistance and flexibility for indoor industrial environments. The application process generates minimal volatile organic compounds and allows for efficient material utilization through recapture and reuse of overspray powder.

Hot-Dip Galvanizing Process Optimization

Modern hot-dip galvanizing processes have evolved to provide enhanced coating quality and consistency for cable trays. Pre-treatment sequences including caustic cleaning, acid pickling, and fluxing ensure optimal surface preparation for zinc adhesion. Bath composition control and temperature management create uniform coating thickness while minimizing zinc consumption and environmental impact. Post-galvanizing treatments such as quenching and passivation further enhance coating performance and appearance.

Quality control measures including coating thickness testing, adhesion verification, and visual inspection ensure consistent protection levels across production runs. Advanced galvanizing facilities utilize automated handling systems that minimize coating damage and maintain dimensional tolerances critical for cable tray assembly and installation. The resulting finishes provide decades of maintenance-free service while meeting stringent environmental and safety standards.

Material Selection Criteria for Specific Applications

Industrial Environment Assessment

Proper material selection for cable trays requires comprehensive evaluation of environmental conditions, loading requirements, and installation constraints. Temperature extremes, humidity levels, chemical exposures, and atmospheric contaminants all influence material performance and service life expectations. Industrial facilities processing corrosive chemicals demand different material specifications than clean office environments or outdoor utility installations. Load analysis must consider not only static cable weights but also dynamic forces from thermal expansion, seismic activity, and maintenance access requirements.

Geographic factors including coastal proximity, industrial pollution levels, and climatic conditions significantly impact material durability. Salt spray environments require enhanced corrosion protection, while extreme temperature cycling may favor materials with superior thermal stability. Fire protection requirements and building code compliance often dictate specific material properties and testing certifications that must be verified during the selection process.

Lifecycle Cost Analysis

Total cost of ownership for cable trays extends far beyond initial material and installation costs to include maintenance, replacement, and operational considerations throughout the facility lifecycle. Premium materials with higher initial costs often provide superior value through reduced maintenance requirements, extended service life, and improved reliability. Labor costs for maintenance access, coating renewal, and system modifications can significantly exceed original installation expenses in industrial environments with aggressive operating conditions.

Energy efficiency considerations include thermal performance impacts on cable current-carrying capacity and the facility's overall electrical system efficiency. Materials with superior thermal conductivity can reduce cable derating requirements, allowing smaller conductor sizes and reduced installation costs. The environmental impact of material production, transportation, and end-of-life disposal increasingly influences selection decisions as sustainability becomes a priority for industrial facilities.

Installation and Maintenance Best Practices

Proper Support and Spacing Requirements

Optimal cable tray performance depends on proper support spacing that considers material properties, load distributions, and deflection limits. Steel cable trays typically require support intervals of 8 to 12 feet for standard loading conditions, while aluminum systems may need closer spacing due to lower elastic modulus values. FRP cable trays often specify support spacing based on specific load combinations and environmental temperature ranges that affect material stiffness. Proper support design prevents excessive deflection that can create cable stress points and compromise system reliability.

Expansion joint placement becomes critical for long cable tray runs, particularly in outdoor installations or facilities with significant temperature variations. Material thermal expansion coefficients determine joint spacing requirements, with steel systems typically requiring joints every 100 to 150 feet and aluminum systems needing closer intervals. Proper joint design maintains structural continuity while accommodating thermal movement without binding or stress concentration.

Preventive Maintenance Strategies

Effective maintenance programs for cable trays focus on inspection schedules tailored to material types and environmental conditions. Visual inspections should identify coating degradation, corrosion initiation, mechanical damage, and support system integrity issues before they compromise system performance. Galvanized steel cable trays benefit from periodic cleaning and touch-up coating applications at damage points, while stainless steel systems require minimal intervention beyond periodic cleaning to maintain appearance.

Documentation of inspection findings and maintenance activities enables trending analysis that can predict replacement needs and optimize maintenance intervals. Thermal imaging surveys can identify overloaded sections or poor electrical connections that may accelerate material degradation. Proper maintenance planning includes spare parts inventory management and coordination with facility shutdown schedules to minimize operational disruptions during major maintenance activities.

FAQ

What factors determine the optimal material choice for cable trays in industrial applications

Material selection for industrial cable trays depends on environmental conditions, load requirements, installation constraints, and lifecycle cost considerations. Corrosive environments favor stainless steel or FRP materials, while standard industrial applications typically use galvanized steel for optimal cost-performance balance. Temperature extremes, seismic requirements, and fire protection codes also influence material specifications. Proper evaluation includes assessment of atmospheric contaminants, humidity levels, and potential chemical exposures that may affect material durability over the intended service life.

How do different cable tray materials compare in terms of maintenance requirements

Galvanized steel cable trays require periodic inspection for coating integrity and touch-up painting at damage points, typically every 5-10 years depending on environmental conditions. Stainless steel systems need minimal maintenance beyond periodic cleaning, with service intervals extending to 15-20 years in most environments. FRP cable trays require only visual inspection and cleaning, with virtually no coating maintenance needed throughout their service life. Aluminum systems fall between steel and stainless steel in maintenance requirements, with anodized finishes providing long-term protection with minimal intervention needed.

What load-bearing capabilities can be expected from different cable tray materials

Steel cable trays offer the highest load-bearing capacity, typically supporting 150-300 pounds per linear foot depending on configuration and span length. Aluminum systems provide 60-80% of equivalent steel capacity while offering significant weight advantages for installation and support structure requirements. FRP cable trays support moderate loads of 75-150 pounds per linear foot, with capacity depending on fiber content and resin selection. All materials require proper engineering analysis considering dead loads, live loads, and dynamic forces to ensure adequate safety factors throughout the installation.

How does environmental exposure affect the service life of different cable tray materials

Environmental conditions significantly impact cable tray service life, with properly selected materials providing 25-50 years of reliable performance. Galvanized steel systems last 25-35 years in moderate environments but may require earlier replacement in highly corrosive conditions. Stainless steel and FRP materials can exceed 50-year service lives in aggressive environments where other materials fail prematurely. Proper material selection based on specific environmental assessment ensures optimal performance throughout the intended facility lifecycle while minimizing unexpected replacement costs.

Table of Contents

- Steel Construction for Maximum Load Bearing Capacity

- Aluminum Alloy Solutions for Weight-Sensitive Applications

- Fiber Reinforced Plastic Composite Materials

- Surface Treatment Technologies for Enhanced Protection

- Material Selection Criteria for Specific Applications

- Installation and Maintenance Best Practices

-

FAQ

- What factors determine the optimal material choice for cable trays in industrial applications

- How do different cable tray materials compare in terms of maintenance requirements

- What load-bearing capabilities can be expected from different cable tray materials

- How does environmental exposure affect the service life of different cable tray materials