Modern industrial and commercial facilities rely heavily on organized cable management systems to maintain operational efficiency and safety standards. Cable trays serve as the backbone of electrical infrastructure, providing secure pathways for power and data cables throughout buildings, manufacturing plants, and data centers. These engineered support systems ensure proper cable routing while maintaining accessibility for maintenance and future expansions. Understanding the fundamentals of cable tray installation is essential for electrical contractors, facility managers, and engineers who prioritize reliable electrical distribution systems.

Understanding Cable Tray Systems and Components

Types of Cable Tray Configurations

Cable tray systems come in various configurations designed to meet specific application requirements and environmental conditions. Ladder-type cable trays feature side rails connected by rungs, providing excellent ventilation and easy cable access for maintenance purposes. These systems work particularly well in areas where heat dissipation is crucial and cables require frequent inspection or modification. The open design allows for natural cooling while supporting heavy cable loads across long spans.

Perforated cable trays offer a solid bottom with strategically placed holes that balance cable support with ventilation requirements. This design provides better protection for sensitive cables while maintaining adequate airflow for thermal management. Solid bottom cable trays deliver maximum protection against environmental hazards like moisture, dust, and chemical exposure, making them ideal for harsh industrial environments or areas requiring enhanced electromagnetic shielding.

Material Selection and Load Considerations

The choice of cable tray materials significantly impacts system performance, longevity, and installation requirements. Galvanized steel cable trays provide excellent strength-to-weight ratios and cost-effectiveness for most standard applications. These systems handle heavy loads while offering good corrosion resistance through protective zinc coatings. Stainless steel options deliver superior corrosion resistance for chemical processing facilities, marine environments, or food processing applications where hygiene and durability are paramount.

Aluminum cable trays offer lightweight alternatives that simplify installation while providing adequate load capacity for most commercial applications. The natural corrosion resistance of aluminum makes these systems suitable for outdoor installations or environments with moderate chemical exposure. Load calculations must account for cable weights, dynamic forces from thermal expansion, and safety factors specified by electrical codes and manufacturer recommendations.

Pre-Installation Planning and Design Requirements

Route Survey and Space Assessment

Effective cable tray installation begins with comprehensive route surveys that identify optimal pathways while avoiding conflicts with existing infrastructure. Site assessment involves measuring ceiling heights, identifying structural support points, and documenting potential obstacles like HVAC equipment, piping systems, and architectural features. This preliminary work ensures cable tray routes maintain required clearances from other utilities while providing adequate access for installation and maintenance activities.

Environmental factors play crucial roles in route selection and system design. Temperature variations affect cable performance and tray expansion, requiring careful consideration of thermal movement joints and support spacing. Humidity levels, chemical exposure risks, and seismic requirements influence material selection and mounting methods. Proper documentation during the survey phase prevents costly modifications during installation and ensures compliance with applicable building codes.

Support Structure Design and Engineering

Cable tray support systems must withstand calculated loads while maintaining structural integrity throughout the system's operational life. Support spacing depends on tray width, material properties, cable loading, and span requirements specified by manufacturers and electrical codes. Typical support intervals range from six to twelve feet, with closer spacing required for heavily loaded systems or areas subject to seismic activity.

Structural attachment methods vary based on building construction and load requirements. Concrete anchors provide secure mounting for permanent installations in masonry or concrete structures. Steel beam clamps offer adjustable solutions for metal building frames, while threaded rod assemblies enable precise positioning and load distribution. All support hardware must meet or exceed specified load ratings and include appropriate safety factors for dynamic loading conditions.

Installation Procedures and Best Practices

Foundation and Support Installation

Installing cable tray supports begins with accurate layout marking using laser levels and measuring tools to ensure proper alignment and elevation throughout the system. Structural attachments must be installed according to manufacturer specifications and local building codes, with particular attention to anchor spacing, torque requirements, and load ratings. Wall-mounted supports require solid backing or adequate reinforcement to handle distributed loads from cable-filled trays.

Ceiling-mounted installations often utilize threaded rod hangers that provide adjustability for final positioning and leveling. These systems must account for building movement, thermal expansion, and potential load increases from future cable additions. Proper installation includes using appropriate rod couplings, beam attachments, and safety cables where required by local codes or seismic considerations.

Tray Assembly and Mounting Techniques

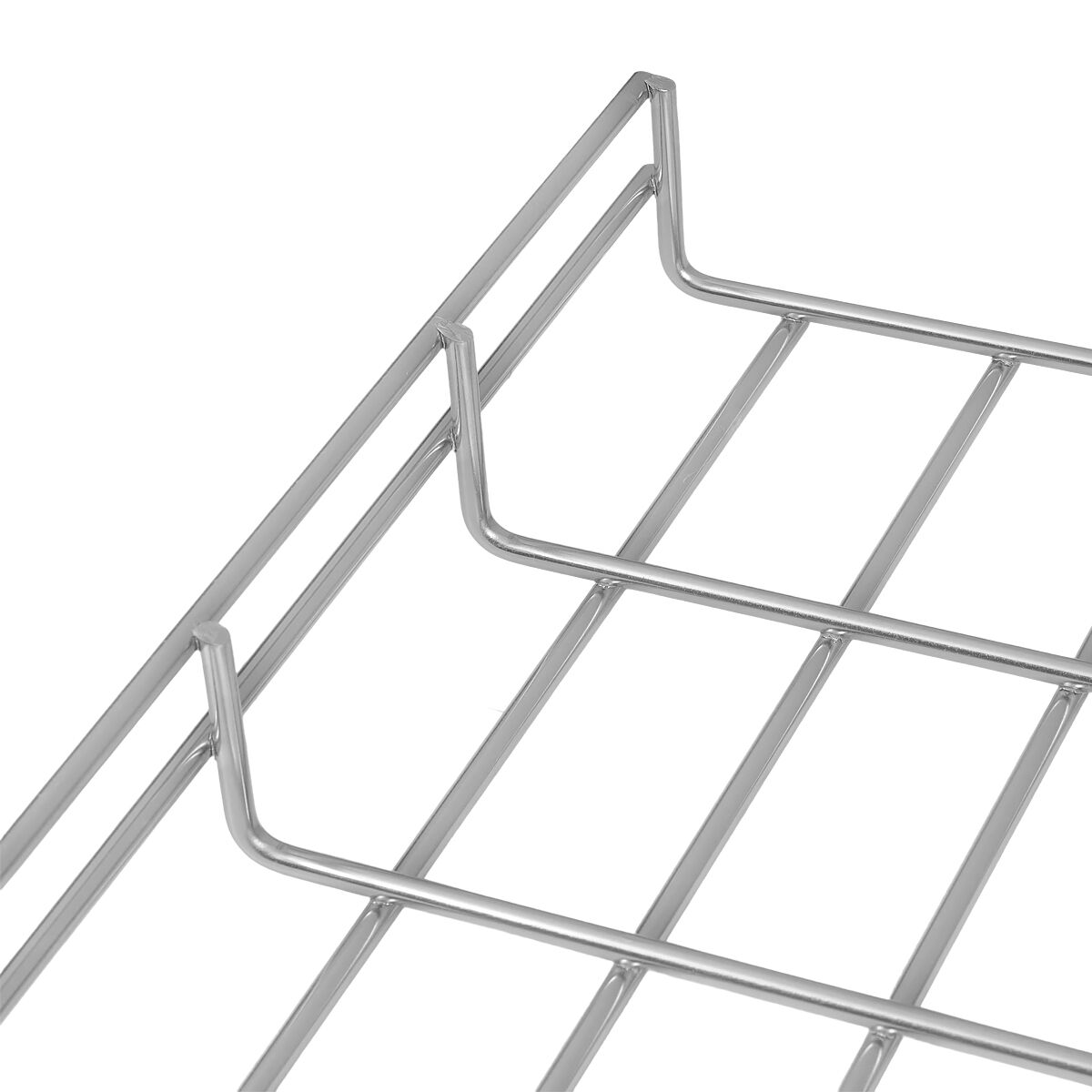

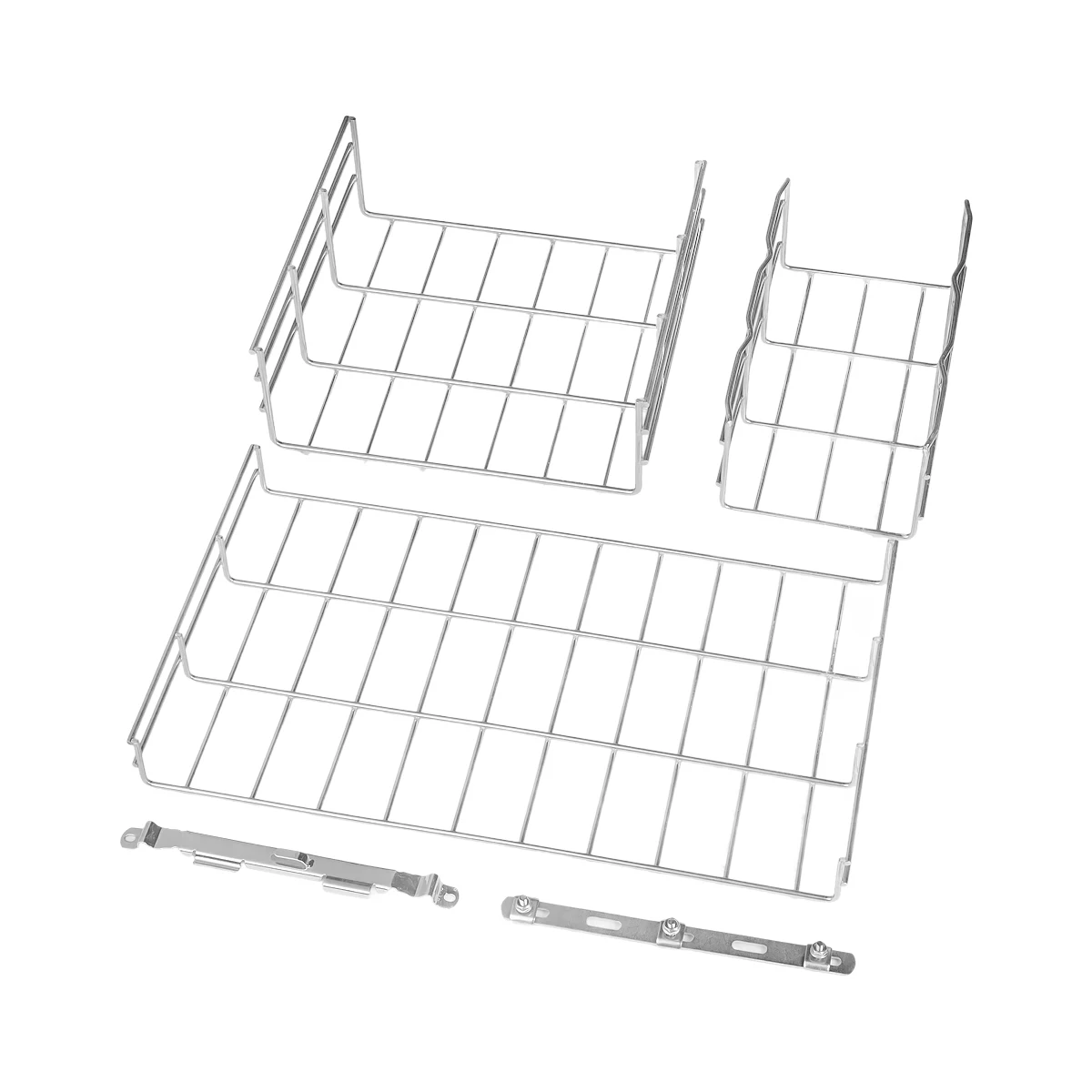

Cable tray sections connect using manufacturer-supplied splice plates and hardware designed to maintain structural continuity and electrical bonding. Joint connections require proper torque application to prevent loosening from vibration or thermal cycling while avoiding over-tightening that could damage tray materials. Expansion joints accommodate thermal movement in long runs, preventing stress concentrations that could lead to system failure.

During assembly, maintaining proper tray alignment ensures smooth cable installation and prevents binding or damage during pulling operations. Cable trays must be level both longitudinally and laterally to prevent cable pooling and ensure even load distribution. Temporary bracing may be necessary during installation to maintain alignment until all connections are completed and the system achieves full structural integrity.

Safety Protocols and Code Compliance

Electrical Safety and Grounding Requirements

Proper electrical grounding of cable tray systems protects personnel and equipment while ensuring code compliance and system reliability. Metallic cable trays must be bonded to the building's electrical grounding system using approved conductors and connection methods. Grounding connections require clean metal surfaces free from paint, corrosion, or other materials that could impede electrical continuity.

Bonding jumpers maintain electrical continuity across tray joints and expansion connections where structural splice plates may not provide adequate electrical contact. These connections must be sized according to electrical code requirements and installed using approved hardware designed for the specific tray material and environmental conditions. Regular inspection and testing verify grounding system integrity throughout the installation's operational life.

Fire Safety and Material Standards

Fire-rated cable tray installations require specific materials and installation methods to maintain building fire protection systems. These systems must comply with applicable fire codes and may require additional protection like fire-resistant coatings or enclosures in critical areas. Cable fill restrictions help prevent overheating and maintain proper ventilation for thermal management under normal and emergency conditions.

Material certifications ensure cable tray components meet required safety standards and performance criteria. UL listing, galvanizing specifications, and load test certifications provide verification that installed systems will perform as designed under specified conditions. Documentation of these certifications supports inspection processes and demonstrates compliance with applicable codes and standards.

Cable Installation and Load Management

Cable Pulling and Support Techniques

Proper cable installation techniques prevent damage while ensuring optimal system performance and longevity. Cable pulling operations require careful planning to minimize stress on both cables and tray systems. Pull lengths should be limited based on cable type, tray configuration, and available pulling equipment to prevent excessive tension that could damage conductor insulation or strain tray supports.

Cable support within trays involves strategic placement of tie-downs and supports that secure cables without restricting thermal movement or creating stress concentrations. Spacing requirements vary by cable type and installation environment, with closer support needed for vertical runs or areas subject to vibration. Proper support prevents cable sagging that could interfere with tray covers or create maintenance hazards.

Load Distribution and Fill Calculations

Calculating cable loads ensures tray systems operate within design parameters while maintaining safety margins for future expansion. Load calculations include cable weights, dynamic factors from thermal cycling, and distribution patterns that affect support requirements. Non-uniform loading requires careful analysis to prevent overloading individual support points or tray sections.

Fill calculations determine maximum cable capacity based on tray dimensions, ventilation requirements, and heat dissipation needs. Overfilled trays can lead to overheating, reduced cable life, and increased fire risks. Proper fill levels maintain adequate spacing for air circulation while leaving room for future cable additions without system modifications or upgrades.

Maintenance and Long-Term Performance

Inspection Protocols and Preventive Maintenance

Regular inspection programs identify potential issues before they compromise system reliability or safety. Visual inspections focus on support integrity, tray alignment, cable condition, and environmental factors that could affect system performance. Inspection frequencies depend on installation environment, with harsh conditions requiring more frequent monitoring than controlled indoor environments.

Preventive maintenance includes cleaning accumulated debris, checking connection torque, and verifying grounding system continuity. Thermal imaging can identify hot spots indicating overloaded circuits or poor connections requiring immediate attention. Documentation of inspection findings supports predictive maintenance programs and helps identify trends that could indicate developing problems.

System Modifications and Expansion Planning

Future system modifications require careful evaluation of existing capacity and structural limitations to ensure safe and compliant installations. Adding cables to existing trays involves recalculating loads and verifying adequate support capacity for increased weights. New cable routes may require additional tray sections, supports, or routing changes that maintain system integrity while accommodating expanded requirements.

Expansion planning considers both immediate needs and anticipated future growth to minimize installation disruptions and optimize long-term costs. Oversizing initial installations within reasonable limits provides flexibility for future needs while avoiding excessive upfront costs. Modular tray systems facilitate modifications by using standardized components and connection methods that simplify expansion projects.

FAQ

What factors determine the appropriate cable tray size for a specific installation?

Cable tray sizing depends on the total cross-sectional area of cables to be installed, fill factor requirements specified by electrical codes, and future expansion needs. Calculate the combined area of all cables, apply the appropriate fill factor (typically 50% for control cables and 40% for power cables), and select a tray size that accommodates this area while maintaining proper spacing for ventilation and heat dissipation.

How do you ensure proper grounding and electrical continuity in cable tray systems?

Proper grounding requires bonding all metallic tray sections to the building's electrical grounding system using approved conductors sized according to electrical code requirements. Install bonding jumpers across all joints and expansion connections, ensure clean metal-to-metal contact at all connection points, and verify continuity through testing. All grounding connections must be accessible for inspection and maintenance throughout the system's operational life.

What are the key considerations for cable tray installations in outdoor or harsh environments?

Outdoor installations require materials with enhanced corrosion resistance, such as hot-dip galvanized steel or stainless steel, along with covers to protect cables from weather exposure. Consider thermal expansion effects from temperature variations, drainage requirements to prevent water accumulation, and seismic bracing where required by local codes. UV-resistant cable jackets and appropriate tray coatings help ensure long-term performance under environmental stresses.

How do you calculate support spacing and load requirements for cable tray systems?

Support spacing calculations consider tray material properties, cable loading, span requirements, and safety factors specified by manufacturers and electrical codes. Calculate total cable weight, add appropriate safety factors (typically 1.5 to 2.0), and determine maximum allowable spans based on tray deflection limits. Support loads include both vertical forces from cable weight and lateral forces from cable pulling operations or seismic activity, requiring proper anchor sizing and installation techniques.

Table of Contents

- Understanding Cable Tray Systems and Components

- Pre-Installation Planning and Design Requirements

- Installation Procedures and Best Practices

- Safety Protocols and Code Compliance

- Cable Installation and Load Management

- Maintenance and Long-Term Performance

-

FAQ

- What factors determine the appropriate cable tray size for a specific installation?

- How do you ensure proper grounding and electrical continuity in cable tray systems?

- What are the key considerations for cable tray installations in outdoor or harsh environments?

- How do you calculate support spacing and load requirements for cable tray systems?