Selecting the appropriate power transformer for commercial applications requires careful consideration of multiple technical and operational factors. Commercial facilities demand reliable electrical infrastructure that can handle varying load requirements while maintaining efficiency and safety standards. Understanding the fundamental characteristics of different transformer types, their operational parameters, and installation requirements becomes crucial for project success. The decision-making process involves evaluating power requirements, environmental conditions, space constraints, and long-term operational costs to ensure optimal performance throughout the transformer's service life.

Understanding Commercial Power Transformer Requirements

Load Analysis and Capacity Planning

Commercial power transformer selection begins with comprehensive load analysis to determine the required capacity and operating characteristics. Engineers must evaluate both current electrical demands and future expansion plans to avoid undersizing or oversizing the installation. Peak load calculations should include all connected equipment, lighting systems, HVAC units, and any specialized machinery that may operate simultaneously. Diversity factors and load growth projections help establish the minimum transformer rating needed for reliable operation.

Power quality requirements also influence transformer selection, as commercial facilities often house sensitive electronic equipment requiring stable voltage regulation. Harmonic distortion levels from non-linear loads must be considered when specifying transformer impedance and thermal capacity. Modern commercial buildings typically require transformers capable of handling variable frequency drives, computer systems, and LED lighting that can introduce harmonic currents into the electrical system.

Voltage Classification and System Configuration

Commercial installations typically involve medium voltage primary systems feeding low voltage secondary distribution networks. Common voltage configurations include 4160V to 480V, 13.8kV to 480V, or 34.5kV to 4160V depending on the facility size and utility supply characteristics. Delta-wye configurations provide neutral grounding for single-phase loads while maintaining three-phase capability for motor loads and other industrial equipment.

System grounding requirements influence transformer connection types and affect overall electrical safety protocols. Solidly grounded wye secondary systems offer superior fault protection and allow for effective ground fault detection systems. The selection process must align with local electrical codes and utility interconnection standards to ensure compliance and safe operation throughout the installation's operational life.

Transformer Technology Types and Applications

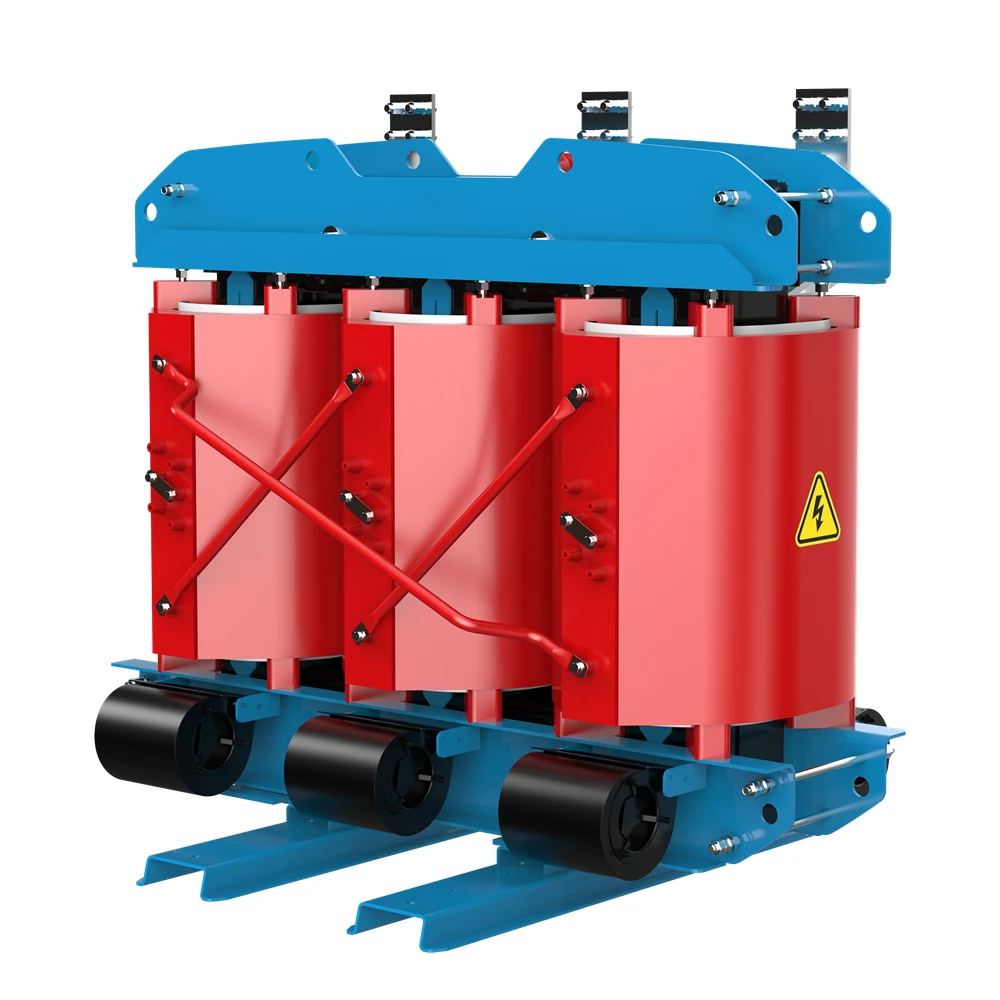

Liquid-Filled vs Dry-Type Transformers

Commercial facilities can utilize either liquid-filled or dry-type transformers depending on installation location, fire safety requirements, and maintenance preferences. Liquid-filled units offer superior cooling capacity and longer service life but require containment systems and regular oil maintenance. These transformers excel in outdoor applications or dedicated electrical rooms where space allows for proper clearances and environmental controls.

Dry-type transformers provide excellent safety characteristics for indoor installations, eliminating fire and environmental hazards associated with insulating fluids. Cast resin and ventilated dry-type designs offer reliable performance in commercial settings while requiring minimal maintenance throughout their operational life. The selection between these technologies depends on installation environment, local fire codes, and long-term operational considerations specific to each commercial application.

Efficiency Standards and Energy Considerations

Modern commercial facilities increasingly prioritize energy efficiency to reduce operational costs and meet sustainability goals. High-efficiency power transformer designs utilize advanced core materials and winding techniques to minimize no-load and load losses. Premium efficiency units may justify higher initial costs through reduced energy consumption over the transformer's 25-30 year service life.

Load characteristics significantly impact efficiency performance, as transformers operate most efficiently at 75-85% of rated capacity. Facilities with consistent loading patterns benefit from properly sized units, while those with highly variable loads may require multiple smaller transformers or units with enhanced part-load efficiency characteristics. Energy monitoring capabilities integrated into modern transformer designs provide valuable operational data for facility management and predictive maintenance programs.

Installation and Environmental Factors

Space Requirements and Physical Constraints

Commercial power transformer installations must accommodate physical space limitations while meeting safety clearance requirements. Indoor installations require adequate ventilation for heat dissipation and maintenance access for routine inspections and potential repairs. Ceiling height, floor loading capacity, and access routes for equipment delivery influence transformer selection and installation planning.

Outdoor installations offer greater flexibility in transformer sizing but require weather protection and security considerations. Pad-mounted transformers provide ground-level access for maintenance while vault installations offer enhanced security and aesthetic benefits. The selection process must balance space utilization efficiency with operational accessibility and safety requirements throughout the installation's service life.

Environmental Operating Conditions

Operating environment significantly affects transformer performance and longevity in commercial applications. Temperature extremes, humidity levels, altitude, and contamination exposure influence insulation system selection and cooling requirements. Coastal installations may require enhanced corrosion protection, while facilities in seismic zones need appropriate mounting and bracing systems.

Indoor air quality considerations include dust levels, chemical vapors, and ventilation requirements that affect transformer cooling and insulation integrity. Specialized enclosures or filtration systems may be necessary in challenging environments to maintain reliable operation. Environmental monitoring systems can provide early warning of conditions that might compromise transformer performance or accelerate aging processes.

Protection and Control System Integration

Protective Device Coordination

Commercial power transformer protection requires coordination with upstream and downstream protective devices to ensure selective fault clearing and system reliability. Primary and secondary fusing or circuit breaker protection must be sized and coordinated to protect the transformer while maintaining service continuity for unaffected portions of the electrical system.

Ground fault protection systems become particularly important in commercial facilities where personnel safety and equipment protection are paramount concerns. Transformer differential protection may be justified for larger units or critical applications where rapid fault clearing prevents extensive damage. Protection system design must comply with applicable electrical codes while providing appropriate sensitivity for reliable operation.

Monitoring and Communication Capabilities

Modern commercial facilities increasingly integrate transformer monitoring systems with building management networks for enhanced operational visibility and predictive maintenance capabilities. Temperature monitoring, load current measurement, and power quality analysis provide valuable data for optimizing system performance and identifying potential issues before failures occur.

Communication protocols such as Modbus, BACnet, or Ethernet enable integration with facility monitoring systems and remote access capabilities. Smart transformer technologies offer advanced diagnostics including dissolved gas analysis, partial discharge monitoring, and thermal imaging integration. These capabilities support condition-based maintenance strategies that can extend transformer life and reduce unplanned downtime.

Economic Analysis and Life-Cycle Considerations

Initial Cost vs Long-Term Value

Commercial power transformer selection requires comprehensive economic analysis comparing initial purchase price with long-term operational costs. Higher efficiency units typically command premium pricing but deliver savings through reduced energy losses over the equipment's service life. The economic analysis must include energy costs, maintenance requirements, and potential downtime costs to determine the most cost-effective solution.

Financing options and utility rebate programs may influence the economic viability of premium efficiency equipment. Some utility companies offer incentives for high-efficiency transformer installations that reduce system losses and improve overall grid efficiency. Life-cycle cost analysis should extend 20-30 years to capture the full economic impact of transformer selection decisions.

Maintenance and Service Considerations

Long-term maintenance requirements vary significantly between transformer technologies and directly impact total ownership costs. Liquid-filled units require periodic oil testing and potential oil replacement, while dry-type transformers need primarily visual inspections and cleaning procedures. Service accessibility and spare parts availability influence maintenance costs and system reliability.

Manufacturer support capabilities including warranty terms, service network coverage, and technical support availability should factor into selection decisions. Standardizing on specific manufacturers or product lines can simplify maintenance procedures and inventory management while potentially reducing costs through volume purchasing agreements. Training requirements for facility maintenance staff may also influence technology selection decisions.

FAQ

What size power transformer do I need for my commercial building?

Commercial transformer sizing depends on total connected load, demand factors, and future expansion plans. Calculate the maximum expected demand including all electrical equipment, lighting, and HVAC systems, then add 25-50% capacity for future growth. A qualified electrical engineer should perform load calculations considering diversity factors and local code requirements to determine the appropriate transformer rating.

How do I choose between dry-type and liquid-filled transformers?

The choice depends primarily on installation location and fire safety requirements. Dry-type transformers are preferred for indoor installations due to fire safety advantages and minimal maintenance requirements. Liquid-filled units offer better cooling capacity and longer life for outdoor installations or dedicated electrical rooms where fire protection systems and containment can be provided.

What efficiency level should I specify for commercial applications?

Specify the highest efficiency level that provides positive life-cycle economics for your application. Premium efficiency transformers typically offer 1-2% better efficiency than standard units, which can provide significant energy savings over 25-30 year service life. Consider local energy costs, utility incentives, and sustainability goals when making efficiency decisions.

How important is manufacturer selection for commercial transformers?

Manufacturer selection is crucial for long-term reliability and support. Choose established manufacturers with proven commercial track records, comprehensive warranty coverage, and local service support. Consider factors such as delivery time, technical support quality, spare parts availability, and compatibility with existing equipment when evaluating potential suppliers.