Electrical power distribution systems form the backbone of modern civilization, enabling everything from residential lighting to industrial manufacturing processes. At the heart of these complex networks lie power transformers, sophisticated electrical devices that play a crucial role in maintaining voltage stability and ensuring efficient energy transmission across vast distances. These remarkable machines have revolutionized how electricity reaches end users, making it possible to generate power at centralized locations and distribute it safely to millions of consumers worldwide.

The fundamental principle behind electrical power distribution involves stepping voltage levels up and down to optimize transmission efficiency while maintaining safety standards. High voltage transmission reduces energy losses over long distances, while lower voltages ensure safe delivery to residential and commercial consumers. This intricate balance requires sophisticated equipment capable of handling massive electrical loads while maintaining precise voltage regulation under varying demand conditions.

Understanding the mechanisms that enable stable electricity distribution provides valuable insights into the engineering marvels that power our daily lives. From the massive transmission substations that interconnect regional grids to the neighborhood distribution transformers that supply individual buildings, each component serves a specific purpose in the grand orchestration of electrical energy delivery.

Core Functions in Electrical Distribution Networks

Voltage Level Management

Voltage transformation represents the primary function that enables efficient electrical power distribution across diverse applications and geographic regions. Generation facilities typically produce electricity at relatively moderate voltage levels, usually between 11kV and 25kV, which must be stepped up to transmission levels ranging from 138kV to 765kV for long-distance transport. This voltage elevation dramatically reduces current flow for the same power transfer, minimizing resistive losses in transmission lines that can span hundreds of miles.

At distribution substations, power transformers systematically reduce these high transmission voltages to medium distribution levels, typically 4kV to 35kV, suitable for local area networks. This intermediate voltage level provides an optimal balance between safety considerations and transmission efficiency for urban and suburban distribution systems. The precise voltage regulation at this stage directly impacts power quality and system reliability for thousands of connected customers.

Distribution transformers complete the voltage reduction process by stepping down medium voltage to standard utilization levels, such as 120V, 240V, or 480V for residential, commercial, and light industrial applications. These final transformation stages must maintain tight voltage regulation to ensure proper operation of sensitive electronic equipment and appliances that require stable power supply conditions.

Load Balancing and System Stability

Electrical demand fluctuates continuously throughout daily cycles, seasonal patterns, and unexpected events, requiring distribution networks to adapt dynamically to changing load conditions. Transformers equipped with tap changing mechanisms can adjust their transformation ratios to maintain voltage stability as system loading varies. This capability proves essential during peak demand periods when heavy loading can cause voltage drops that affect power quality and equipment performance.

The strategic placement of multiple transformers throughout distribution networks creates redundancy and load sharing opportunities that enhance overall system reliability. When one transformer experiences failure or requires maintenance, alternative power paths through adjacent transformers can maintain service continuity for affected customers. This network configuration requires careful coordination of transformer capacities and impedance characteristics to ensure proper load distribution.

Advanced monitoring systems integrated with modern transformers provide real-time data on loading conditions, temperature profiles, and electrical parameters that enable proactive system management. Operators can identify developing issues before they cause service interruptions and optimize transformer loading to maximize equipment life while maintaining adequate reserve capacity for emergency conditions.

Technological Innovations in Transformer Design

Smart Grid Integration Capabilities

Contemporary power transformers incorporate sophisticated monitoring and communication technologies that enable seamless integration with smart grid infrastructure. Digital sensors continuously measure critical operating parameters including load current, voltage levels, oil temperature, and dissolved gas concentrations that indicate potential internal faults. This real-time data streams to centralized control systems that can automatically adjust network configurations to optimize performance and prevent equipment damage.

Remote switching capabilities allow operators to reconfigure distribution networks from central control rooms, enabling rapid response to changing load conditions or equipment failures. These systems can automatically isolate faulted sections while maintaining power delivery to unaffected areas, significantly reducing outage duration and improving customer satisfaction. The integration of renewable energy sources also benefits from smart transformer technologies that can accommodate bidirectional power flows and variable generation patterns.

Predictive maintenance algorithms analyze historical operating data to identify trends that precede equipment failures, enabling maintenance teams to address issues during planned outages rather than emergency responses. This proactive approach reduces maintenance costs while improving system reliability by preventing unexpected transformer failures that can cascade into widespread outages.

Environmental Considerations and Efficiency Improvements

Modern transformer designs prioritize environmental sustainability through improved efficiency ratings and reduced environmental impact during manufacturing and operation. High-efficiency transformers can achieve energy losses below 0.5% of rated capacity, representing significant energy savings when applied across thousands of units in distribution networks. These efficiency improvements translate directly into reduced greenhouse gas emissions from power generation facilities.

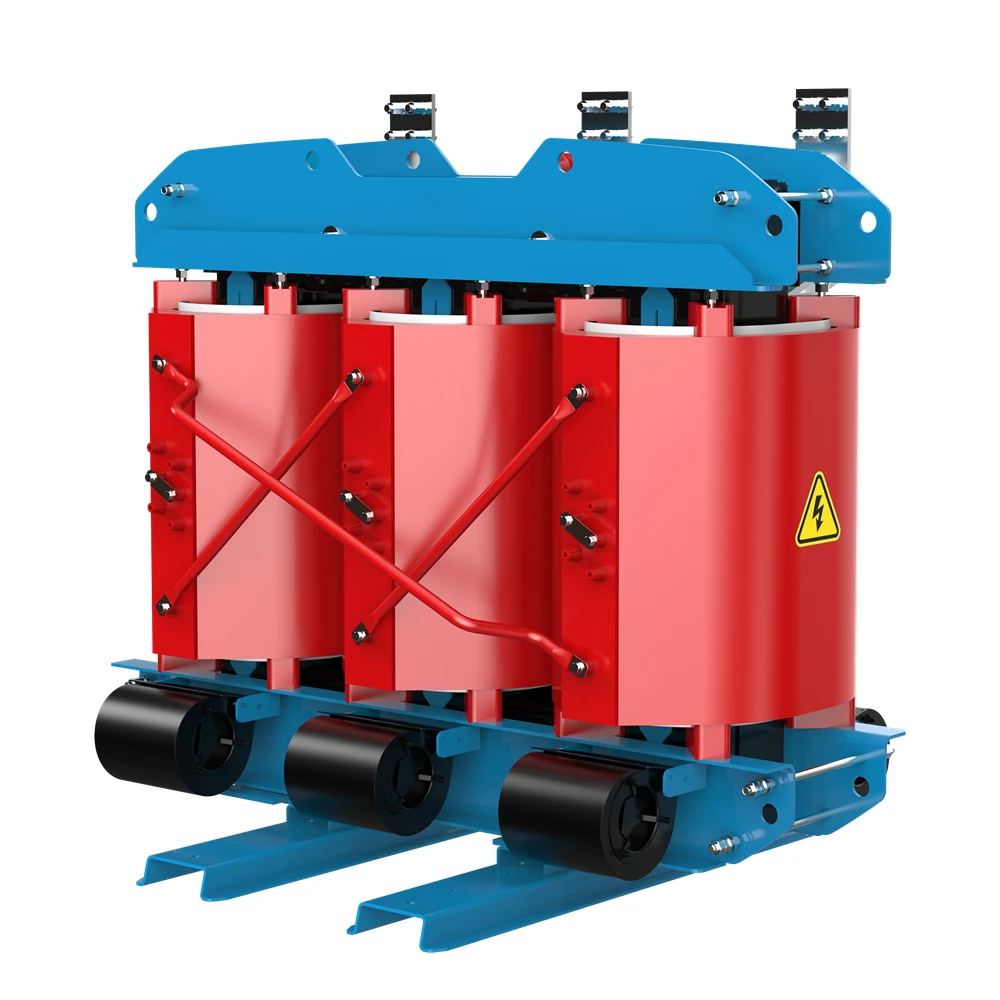

Dry-type transformer technologies eliminate the need for insulating oils that pose environmental risks in case of spills or leaks. These designs use solid insulation systems that provide equivalent electrical performance while eliminating concerns about oil contamination and disposal. Cast resin insulation systems offer particularly robust performance in harsh environmental conditions while maintaining compact designs suitable for urban installations.

Recyclable materials and sustainable manufacturing processes increasingly characterize modern transformer production, addressing end-of-life environmental concerns. Copper windings, silicon steel cores, and aluminum components can be recovered and reused in new equipment, reducing the environmental footprint of electrical infrastructure development. These considerations align with broader sustainability initiatives while maintaining the technical performance required for reliable power distribution.

Installation and Maintenance Best Practices

Site Preparation and Safety Requirements

Proper transformer installation begins with comprehensive site evaluation and preparation that addresses electrical, mechanical, and environmental requirements. Foundation design must accommodate the substantial weight of power transformers while providing adequate drainage and access for maintenance activities. Electrical clearances around transformer installations must comply with safety codes that specify minimum distances from buildings, property lines, and other electrical equipment.

Grounding systems for transformer installations require careful design to ensure personnel safety and proper equipment operation under both normal and fault conditions. Multiple grounding electrodes connected to transformer tanks and neutral points create low-impedance paths for fault currents while preventing dangerous voltage buildup on metallic structures. These grounding networks must be tested and verified before energization to confirm compliance with safety standards.

Fire protection considerations become critical for oil-filled transformers that contain substantial quantities of flammable insulating oil. Proper spacing between adjacent transformers, installation of fire barriers, and provision of oil containment systems help prevent fire spread and environmental contamination. Emergency response procedures must be established and communicated to local fire departments to ensure appropriate response to transformer-related incidents.

Preventive Maintenance Strategies

Routine maintenance programs for power transformers focus on condition assessment techniques that identify developing problems before they cause equipment failure. Oil analysis provides detailed information about internal transformer condition by detecting dissolved gases that indicate overheating, arcing, or insulation degradation. Regular sampling and laboratory analysis of transformer oil enables maintenance teams to track equipment condition trends and schedule interventions appropriately.

Thermographic inspections using infrared cameras can identify hot spots that indicate loose connections, overloaded components, or inadequate cooling system performance. These non-invasive diagnostic techniques allow maintenance personnel to assess transformer condition without de-energizing equipment, minimizing service interruptions while gathering critical condition data. Trending of temperature measurements over time provides insights into developing problems that require attention.

Electrical testing procedures including insulation resistance measurements, power factor testing, and turns ratio verification provide quantitative assessment of transformer electrical performance. These tests can identify insulation deterioration, winding problems, or tap changer malfunctions that affect transformer operation. Comparison of test results with baseline measurements and manufacturer specifications helps determine when corrective maintenance or replacement becomes necessary.

Economic Impact and System Reliability

Cost-Benefit Analysis of Modern Transformer Technologies

Investment in advanced transformer technologies generates substantial long-term economic benefits through improved efficiency, reduced maintenance costs, and enhanced system reliability. High-efficiency transformers command premium initial costs but deliver energy savings that accumulate over 30-year service lives, typically providing positive return on investment within 5-7 years. These economic benefits become more pronounced as energy costs increase and environmental regulations strengthen.

Reduced maintenance requirements for modern transformer designs lower operational costs while improving system availability. Smart monitoring systems enable condition-based maintenance strategies that optimize maintenance intervals based on actual equipment condition rather than fixed schedules. This approach reduces unnecessary maintenance activities while ensuring interventions occur before equipment failure, minimizing both planned and unplanned outage costs.

System reliability improvements delivered by modern power transformers translate into significant economic value for utility companies and their customers. Reduced outage frequency and duration prevent business interruptions, equipment damage, and customer dissatisfaction that can result in regulatory penalties and revenue losses. The economic value of improved reliability often exceeds the incremental cost of advanced transformer technologies.

Grid Modernization and Future Considerations

Aging electrical infrastructure presents significant challenges as existing transformers reach end-of-life while electrical demand continues growing. Strategic replacement programs must balance immediate reliability needs with long-term system development goals, considering factors such as load growth projections, renewable energy integration requirements, and smart grid capabilities. These decisions require careful analysis of technical and economic factors to optimize infrastructure investments.

Integration of distributed energy resources including solar panels, wind turbines, and energy storage systems requires transformer capabilities that accommodate bidirectional power flows and variable generation patterns. Traditional distribution networks designed for unidirectional power flow must adapt to accommodate these new operating conditions while maintaining voltage stability and power quality. Advanced transformer technologies provide the flexibility needed for this transition.

Climate change adaptation requires transformer designs that can operate reliably under increasingly extreme weather conditions including higher ambient temperatures, severe storms, and flooding events. Resilient infrastructure design incorporates redundancy, weatherproofing, and rapid restoration capabilities that minimize climate-related service disruptions. These considerations influence transformer selection and installation practices as utilities prepare for changing environmental conditions.

FAQ

What is the typical lifespan of power transformers in distribution systems

Power transformers typically provide 25-40 years of reliable service when properly maintained and operated within design parameters. Factors affecting lifespan include loading patterns, environmental conditions, maintenance quality, and initial design specifications. Oil-filled transformers often achieve longer service lives than dry-type units due to superior cooling and insulation characteristics, though both technologies can provide decades of reliable operation when appropriately applied.

How do smart transformers differ from conventional units

Smart transformers incorporate advanced monitoring, communication, and control capabilities that enable real-time performance optimization and predictive maintenance. These units feature digital sensors, remote switching capabilities, and integration with centralized control systems that allow operators to monitor condition parameters, adjust operating characteristics, and respond rapidly to changing system conditions. Conventional transformers rely on manual monitoring and maintenance procedures that provide less operational flexibility.

What factors determine transformer capacity requirements for specific applications

Transformer capacity selection depends on connected load characteristics, growth projections, redundancy requirements, and operating conditions. Peak demand analysis, load diversity factors, and future development plans influence capacity decisions, while safety margins ensure adequate performance under emergency conditions. Environmental factors such as ambient temperature, altitude, and installation conditions also affect capacity ratings and selection criteria.

How do environmental regulations impact transformer selection and operation

Environmental regulations increasingly influence transformer technology choices through efficiency standards, insulating fluid requirements, and end-of-life disposal provisions. Energy efficiency regulations mandate minimum performance levels that favor high-efficiency designs, while environmental protection laws restrict use of certain insulating fluids and require spill containment measures. These regulations drive innovation toward more sustainable transformer technologies that minimize environmental impact throughout their lifecycle.